Concrete Masonry, aka "Rocks-in-a-Box"

- bob habian, aia

- Jul 6, 2018

- 3 min read

Updated: Jul 24, 2018

Concrete Masonry Units (CMU), are simply a modular form of concrete, consisting of a concrete mix design (the “rocks”), which is poured into a steel shape mold (the “box”), and then steam cured, palletized and made ready for shipping, once design strengths are achieved.

MIX DESIGN

The reason we call the concrete a “mix design” is because it is made up of specific ingredients in specific quantities, to meet a series of design and engineering criteria for both color and strength. The ingredients in a mix design typically include some, or all, of the following: .

• Small Aggregates

• Medium Aggregates

• Sand

• Cement

• Water

• Iron Oxide Pigment(s)

• Other Additives (Eg. Integral Water Repellant)

SHAPE

There are literally hundreds of size and shape variations available. Just as the shape of a cake pan will define the shape of a cake, so does the shape of the CMU mold determine the shape of the CMU.

In expressing the size of a CMU, it is necessary to state the dimensions in the proper order – Width, Height and Length. A helpful tool for remembering this is the phrase “Wine Has Legs” (or W x H x L).

Mold options include variations in block width, (4”, 6”, 8”, 10”, 12”, 14” and 16” nominal), block height (4” and 8” nominal), and block length (8”, 16” and 24” nominal). Additionally, both the size of the voids (or “cores”), and the alignment of the core (centered or off-‐set), can be specifically varied. Solid units, without cores, are also available.

A typical unit includes several important elements, including face shells, webs, and cores. The “face shells” are the surfaces facing the inside and outside of the wall. The “web” or “webs” are the portions of the block connecting the two face shells. And the “cores”, are the open voids between the face shells and the webs. However, solid units do not have cores, and thus, do not have face shells nor webs.

Example:

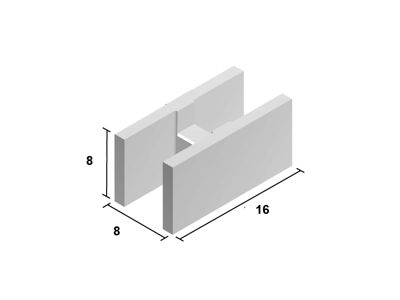

Standard Unit

While this unit may look different than CMU from the past, it is indeed the most popular shape used for fully-grouted and reinforced structures. The ends are open, and the web is lower than the top of the block, allowing room for vertical and horizontal rebar, (more on that later).

Solid Unit

CMU is also available in solid units, particularly for veneer applications, as well as wall cap details. For instance, a common cap shape is a 8x4x16 solid unit, most often made with the same mix design as the wall below the cap.

Dimensions

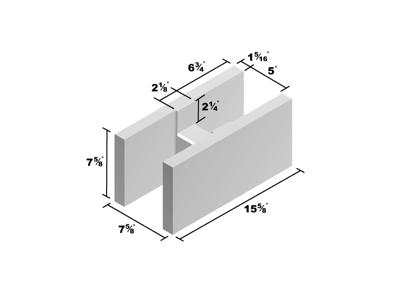

There are three terms used in referring to dimensions: “Specified”, “Actual” and “Nominal”.

Specified Dimensions are those specified for the manufacture of masonry units or the construction of masonry. Calculations are based on specified dimension.

Actual Dimensions are the measured dimension of the unit. UBC/IBC and ASTM Standards allow the actual dimensions a permissible variation from the specified dimension. Each individual product has its respective tolerances.

Nominal Dimensions are those used in stating unit size. They are equal to the specified dimension, plus the thickness of the mortar joint. The nominal dimensions compensate for a 3/8-inch joint for precision and split face, and a 1/2-inch joint for slump block. (For example: if the specified dimension of the most common size precision block is 7-5/8" x 7-5/8" x 15-5/8", the nominal dimension of that same precision block is 8 x 8 x16).

Example: Nominal Dimensions and Actual Dimensions.

As you can imagine, the possibilities are many. To-date, Basalite Concrete Products has produced more than four-thousand concrete mix designs and over four-hundred shapes.

DON'T MISS THIS! Masonry design in REVIT® is easier than ever before!!

Announcing:

For REVIT® users, there is a fantastic new plug-in called MasonryiQ™, which allows you to load color and texture options into a design palette that is project-specific, unleashing you to create unique wall types and calculated blends, using ratios and parameters to better express your ideas. The plug-in also offers intelligent views of corner conditions, window and door openings, as well as control joints and bond beams. You will be amazed at how easy it is to iterate your design ideas, inside of REVIT®, and with built-in BIM intelligence like never before.

Interested in a FREE MasonryiQ™trial? Contact your local Basalite representative for immediate access.

-"Block On!"