Color, Texture & Pattern - You Decide!

- bob habian, aia

- Jul 4, 2018

- 4 min read

Updated: Jul 24, 2018

When you think of "concrete block", do you immediately see just grey and tan, or do you see a rainbow of colors? Well, my friend, the latter is much closer to reality. Concrete masonry is available in more options than you might ever have imagined. And in the digital, retina display world in which we now live, your designs and our products need to keep pace.

Concrete masonry is available in a greater variety of options than you might imagine. In addition to the shape of the unit, you can choose from a variety of colors, face textures, and even patterns.

Now let's take a closer look at each option...

Color

The color of block is determined primarily by the natural color of the aggregates used, as well as added color, in the form of iron oxide pigments. Additional factors affecting block color are the density and strength of the mix design, the type of face texture, and the degree of cleaning and sealing used. It is best to view block as a range of color, rather than not, due to the slight natural variations in materials, and the slight variations possible during normal production, (seasonal and climatic conditions, for instance). Below is an example of just four block colors produced with iron oxide pigments.

Texture

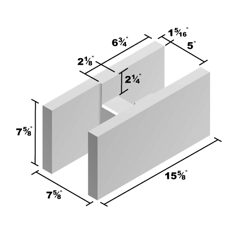

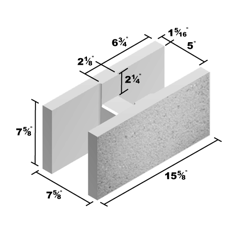

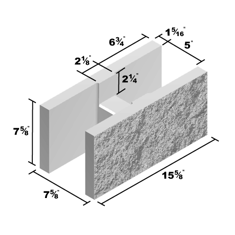

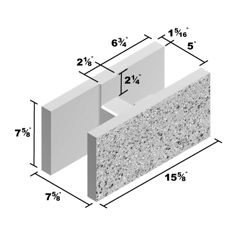

Concrete block comes in a variety of textures, the most commonly used of which, is called "Precision". Shown below are Precision, Shot Blast, Split Face and Ground Face textures, respectively.

Precision

The precision finish is the result of normal production, and has the characteristic of leaving a fairly opaque and consistent outer finish, which results from the finest ingredients in the mix design, (primarily cement and iron oxide pigments, if any), being pushed out to the outer face of the unit by the moisture in the mix design. Because the surface is loaded with the "fines" of the mix, precision units show the most saturation of color. The other textures typically show less cement, less pigment, and more of the inner aggregates.

Shot Blast

The shot blast finish has a stippled or bumpy texture, similar to an "exposed aggregate sidewalk". It is achieved by literally dropping steel beads, (or "shot"), onto the precision finish, which causes the fines of the precision finish to be blasted away, leaving the outer portion of the larger aggregates and a reduced amount of cement and pigment visible. Shot blast can be considered a "pre-weathered" finish, and is an excellent choice for harsh outdoor climates, particularly in coastal conditions.

Split Face

A common texture on many freeway sound walls and buildings, the split face finish is produced by literally splitting two or more units from each other, after they have cured. Therefore, each split face unit is unique, and because the resulting split face dips in and out randomly, these units are produced in a slightly wider size, to ensure that a minimum face shell thickness is maintained, even when the texture dips in. Split face block can be a bit rough to the touch, and therefore is not recommended for interior use where human contact is likely. Similar to shot blast, the split face texture has a "pre-weathered" characteristic and holds up very well in harsher outdoor conditions.

Ground Face

A more expressive option is called split face, and results from grinding the face of a precision unit, until all of the internal aggregates are showing. It has an appearance similar to terrazzo, and can include a number of interesting aggregate colors, depending on the selected mix design. Ground face units are smooth to the touch, and should typically be treated with a post-applied sealer, to bring out the most intense color of the block.

Other Textures

There are additional textures available for CMU, including burnished, high-polish, and even a glazed block finish. These are used less often, and are priced as an ultra premium unit. Contact your product representative anytime to find out more

Pattern

So after you have selected a color and a texture, you may wish to add yet another dimension to the block face, namely a pattern. The most typical patterns are shown below, including Single Score, Multi-Score, Comb Face, and Fluted (deep score), respectively.

Single and Multi-Score

Scored units emulate mortar joints, thus, a single-score 8x8x16 unit, has the appearance of multiple 8x8x8 units, as shown in the first pattern image above. Multi-score units can have the appearance of a "soldier course", with the units looking taller than wider, as shown in the second pattern image above.

Comb Face

The comb face pattern is unique, as it is slightly irregular in the spacing of the vertical striations. The effect is produced by raising the teeth of a mechanical comb vertically against the face of a precision unit, prior to being cured. As the unit cures, it holds the irregular comb pattern. This texture is common on perimeter property walls. An additional attribute to consider is that the pattern is very similar to an "integral scratch coat", over which a cementitious finish can be added. (For example, if the lower portion of a wall was intended to be split face block, with a stucco finish on the upper half, one could simply build the entire wall in CMU, using split face on the bottom, and comb face on the top, with a stucco finish directly applied).

Colors, textures and patterns can enhance your next masonry project. It's always a good idea to explore all options available in your market, by contacting your local product expert for more information.

DON'T MISS THIS! Masonry design in REVIT® is easier than ever before!!

Announcing:

For REVIT® users, there is a fantastic new plug-in called MasonryiQ™, which allows you to load color and texture options into a design palette that is project-specific, unleashing you to create unique wall types and calculated blends, using ratios and parameters to better express your ideas. The plug-in also offers intelligent views of corner conditions, window and door openings, as well as control joints and bond beams. You will be amazed at how easy it is to iterate your design ideas, inside of REVIT®, and with built-in BIM intelligence like never before.

Interested in a FREE MasonryiQ™trial? Contact your local Basalite representative for immediate access.

-"Block On!"